A sieve shaker is used to make sure every particle in a sample has the chance to pass through the openings of the sieves in a stack. In simple terms, its main function is to expose particles to all the mesh openings so that accurate size separation can take place.

Table of Contents

A sieve stack is made by placing sieves on top of each other, starting with the sieve that has the largest mesh openings at the top and gradually moving down to finer mesh sizes. When the sieveshaker operates, it leads to the vibration or shaking of the stack, which helps particles move across each sieve surface. This process ensures a reliable and consistent particle size analysis which is widely used in laboratories, research and industrial applications.

A sieve stack can be made up of anywhere from 1 to 18 sieves, depending on the testing requirements. The number of sieves and their mesh sizes are not chosen at random. Instead, they are usually determined by industry or application standards. In some cases, the production standards of specific products also dictate which sieves should be used.

The optimal motion of a sieveshaker is both circular and vertical which is often described as orbital motion. In simple terms, this motion helps particles move across the sieve surface while also encouraging them to pass through the mesh openings.

Originally, this process was done by hand; a person would rotate the sieve in their hands and tap it on the side to promote particle movement. To improve consistency, the first mechanical sieveshakers were developed. These machines used to rotate an orbital table combined with a hammer that applied vertical tapping at fixed intervals.

This design became known as the Ro/Tap system which is short for rotating and tapping, and it set the foundation for modern sieve shake technology.

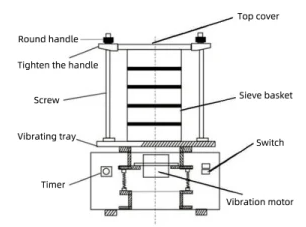

How a Sieve-Shaker Works

A sieveshaker is one of the necessary laboratory instruments that is renowned across many industries such as pharmaceuticals, chemicals, food, and even mining for accurate particle size analysis. It plays an important role in making sure materials are classified correctly and that end products meet with the quality standards.

Putting this simply the main job of a sieve-shaker is to separate and classify particles by size. To do this, a sample is placed on the top sieve in a stack with each sieve below having a finer mesh opening than the one above it. As the sieveshaker operates, the particles gradually separate, which makes it easy to see exactly how the sample is distributed by size. As the sieve-shaker vibrates or shakes the smaller particles pass through each sieve while larger particles remain on top. This results in a clear and reliable particle size distribution of the sample.

Modern sieve shakers are designed to deliver consistent, repeatable and efficient results which makes them inevitable tools in laboratories and production facilities. Depending on the requirement, sieve shakers can vary in design, motion type whether it is orbital, tapping or vibratory, and capacity but their primary goal remains the same which is to simplify and standardize the particle size analysis process

Sieve-Shaker: Working Principle and Process

The working principle of a sieve shaker is quite simple. It uses mechanical vibration to move a stack of sieves and separate particles by size. In practice, the process usually follows these basic steps:

- Sieve Stacking:.In a sieveshaker, the process starts with building a sieve stack. This involves arranging a set of sieves with different mesh sizes on top of each other in descending order. The sieve with the largest openings goes at the top on the other hand the one with the smallest openings is placed at the bottom. Finally, a pan is positioned beneath the stack to collect the finest particles that pass through every sieve.

- Sample Loading: After the sieve stack is prepared, the next step is to load the sample. The material to be tested is first weighed accurately and then placed onto the top sieve in the stack. To get reliable results, it is important that the portion of material used is a true representation of the whole sample. This helps ensure the particle size analysis reflects the actual characteristics of the material being studied.

- Shaking: Thereafter, after the above process, the sieve shaker is activated, and it begins to shake or vibrate the sieve stack. The type of motion can vary depending on the shaker design including circular, vertical or tapping motions.

- Particle Separation: As sieves start shaking, particles smaller than the mesh size of each sieve pass through to the next sieve below. Larger particles are retained on the sieve with the appropriate mesh size.

- Separation Time: Once the sample is loaded, the sieve shaker is run for a set period of time. During this, the Separation gets started, which depends on the type of material being tested and the level of accuracy required. Running the sieve shaker for the right duration gives particles enough time to move through the sieves resulting in accurate, consistent and reliable particle size analysis.

- Weighing Fractions: After the shaking is complete, each sieve is carefully removed from the stack and the material retained on each sieve is weighed. The weight of the material on each sieve represents the fraction of the sample within that specific size range.

- Data Analysis: The weight of data is then used to calculate the particle size distribution of the sample. This data can be presented in various forms such as tables, graphs or cumulative distribution curves.

Working Explained:

Arrangement of sieves in a nest is done with the coarsest at the top. On the top sieve (Figure), a sample of the powder is placed which is 50 grams. For a certain period of time, this sieve set is shaken for 20 minutes with the mechanical shaker apparatus. Each sieve is weighed after it has been shaken.

Uses

- Materials of all kinds are tested for particle size using sieve shakers.

- The machine can handle a maximum of 150 m of coarse material.

- For wet sieve analysis, the material analyzed does not come into contact with the liquid except to be dispersed.

Merits

- It is easy to operate a sieveshaker.

- Samples are separated in a short span of time.

- Only particles with a diameter up to 50 mm can be used.

- Installation takes up less space.

- It is possible to accurately and reproducibly size particles.

- Compared with other methods, this instrument has a lower cost.

Guide to the Various Types of Sieve-Shakers

Several types of sieve shakers are available, and each is designed for specific applications & sample types. The most common types are given as:

- Mechanical Sieve Shakers: These types of shakers use a mechanism to generate the shaking motion. They are generally strong and suitable for a wide range of materials. The motion is usually a combination of horizontal and vertical movement.

- Electromagnetic Sieve Shakers: These shakers use an electromagnetic field to vibrate the sieves. Also, these types of shakers provide precise control over vibration amplitude and frequency, making them ideal for testing sensitive materials.

- Sonic Sieve-Shakers: Sonic sieve shakers use high-frequency sound waves to move and separate particles. They are generally effective for ultra-fine powders and materials that easily clump together.

- Air Jet Sieve Shakers: Air jet sieve shakers use a gentle stream of air to lift and separate particles as they pass through the sieve. These shakers are generally handy for fine, dry powders and materials that tend to clog traditional sieving methods.

- Tapping Sieve-Shakers: Tapping sieve shakers combine shaking and tapping motions to free particles that might get stuck in the sieve mesh, ensuring a more complete separation.

Practical Applications of Sieve-Shakers

Sieve shakers are used across wide range of industries and applications including:

- Construction: One of the key applications is that they are used to measure the particle size distribution of aggregates, sand, and cement. This step is vital for producing high-quality concrete and asphalt with the right strength and durability.

- Pharmaceuticals: Help analyze the particle size of drug powders and granules. This ensures proper dissolution rates, consistent bioavailability and uniform drug formulations.

- Food Industry: Used to measure the particle size of flour, sugar, spices, and other ingredients. Particle size affects texture, taste, and how smoothly products are processed during manufacturing. Interestingly, sieve shakers are now even finding a place in modern kitchens for modern cooking.

- Mining & Minerals: Essential for determining the particle size distribution of ores, minerals, and tailings. This information helps optimize processing operations and improve overall efficiency.

- Chemicals: Used to analyze powders, granules, and other chemical products. Particle size directly influences reactivity, flowability, and stability, also making accurate analysis crucial for reliable performance.

- Agriculture: Help determine the particle size of soil, fertilizers and seeds. This leads to better soil fertility, improved nutrient uptake and higher crop yields.

- Cosmetics: Used to measure the particle size of pigments, powders, and other cosmetic ingredients. Particle size plays a big role in texture, appearance and product performance that ensures smooth and consistent quality.

- Environmental Science: Sieve shakers are used to study the particle size distribution of soil and air pollutants. This analysis is key for analyzing environmental contamination and designing effective strategies.

What Makes Sieve Shakers So Useful

Using sieve shakers for particle size analysis offers several advantages:

- Accuracy: Sieve-shakers deliver precise and reliable particle size distribution data, ensuring consistent and trustworthy test results

- Productivity: Sieve shakers can handle samples quickly and efficiently, which helps in saving not only time but also labor in particle size testing.

- Reliability: Another key advantage of sieve shakers is that they deliver highly dependable Results, and these results ensure consistency along with reliability in every particle size analysis.

- Diverse Applications: Sieve shakers are highly flexible, which makes them suitable for a wide range of materials and particle sizes across different industries.

- Convenience: When it comes to convenience, the Sieve shakers are easy to operate and maintain, which makes them user-friendly for both laboratories and industry.

- Economical: Sieve shakers are a cost-friendly solution for particle size analysis, especially for routine testing.

Conclusion: Role of Sieve-Shakers in Particle Analysis

A sieve shaker is more than just a lab tool, even though it is a reliable way to attain accurate particle size analysis. By classifying particles efficiently, it supports consistent results that are necessary for quality checks, research, and product development.

Nowadays, sieve shakers are used across so many industries, from pharmaceuticals to mining. Understanding their function, working principle, and different types helps in choosing the right equipment. With the proper sieve shaker, the laboratories and industries alike can obtain precise particle size distribution data and maintain the high standards their work demands.

Sieve Shaker | Working Principle, Types & Uses Explained Video.

FAQs About Sieve Shakers

What is a sieve shaker used for?

A sieve-shaker is used to separate and classify particles by size for accurate analysis in labs and industries.

How does a sieve shaker work?

It works by vibrating or shaking a stack of sieves, allowing smaller particles to pass through while larger ones stay on top.

What industries use sieve shakers the most?

They are widely used in pharmaceuticals, food, construction, chemicals, mining, agriculture, and environmental science.

What is the difference between manual sieving and a sieve shaker?

Manual sieving depends on hand shaking and tapping, while sieve – shakers provide consistent, automated motion for more accurate results.

How many sieves can be used in one stack?

Usually between 1 to 18 sieves, depending on testing needs and industry standards.

What types of motions do sieve shakers use?

Common motions include circular, vertical, orbital, tapping, and even air jet or sonic vibrations.

What are the main types of sieve shakers?

Mechanical, electromagnetic, sonic, air jet, and tapping sieveshakers.

Can sieve shakers be used for both dry and wet samples?

Yes, most sieve-shakers can handle both dry sieving and wet sieving, depending on the material.

Why is sieve shaking time important?

If run too short, particles may not separate fully. If too long, it can cause unnecessary wear. The right duration ensures reliable results.

What are the key benefits of using a sieve-shaker?

They are accurate, easy to use, cost-effective, save time, and deliver consistent particle size analysis.