Hot air ovens are important equipment used for sterilization and drying in many industries. Their ability to maintain a constant temperature makes them great choice for processes where precise and calculated heat is required. In this article, we’ll explain what hot air ovens are, how they work, their uses, benefits and maintenance methods.

Table of Contents

What is a Hot Air Oven?

A hot air oven is a type of laboratory equipment used to dry and heat materials. Unlike autoclaves, which use pressurized steam, hot air ovens use circulating air to sterilize. It is used in medical and industrial environments to ensure the cleanliness and safety of equipment and materials.

Looking for Hot Air Oven ?

We are india based Hot Air Oven manufacturers providing 22 Litres to 600 Litres of Hot Air Ovens for all purposes, we can design and manufacture hot air ovens meeting customer provided temperature range, sizes and capacities. Connect at info@bionicsscientific.com

How Does a Hot Air Oven Work?

Hot air ovens heat things evenly by circulating hot air inside the chamber. Here is a simple description of the process.

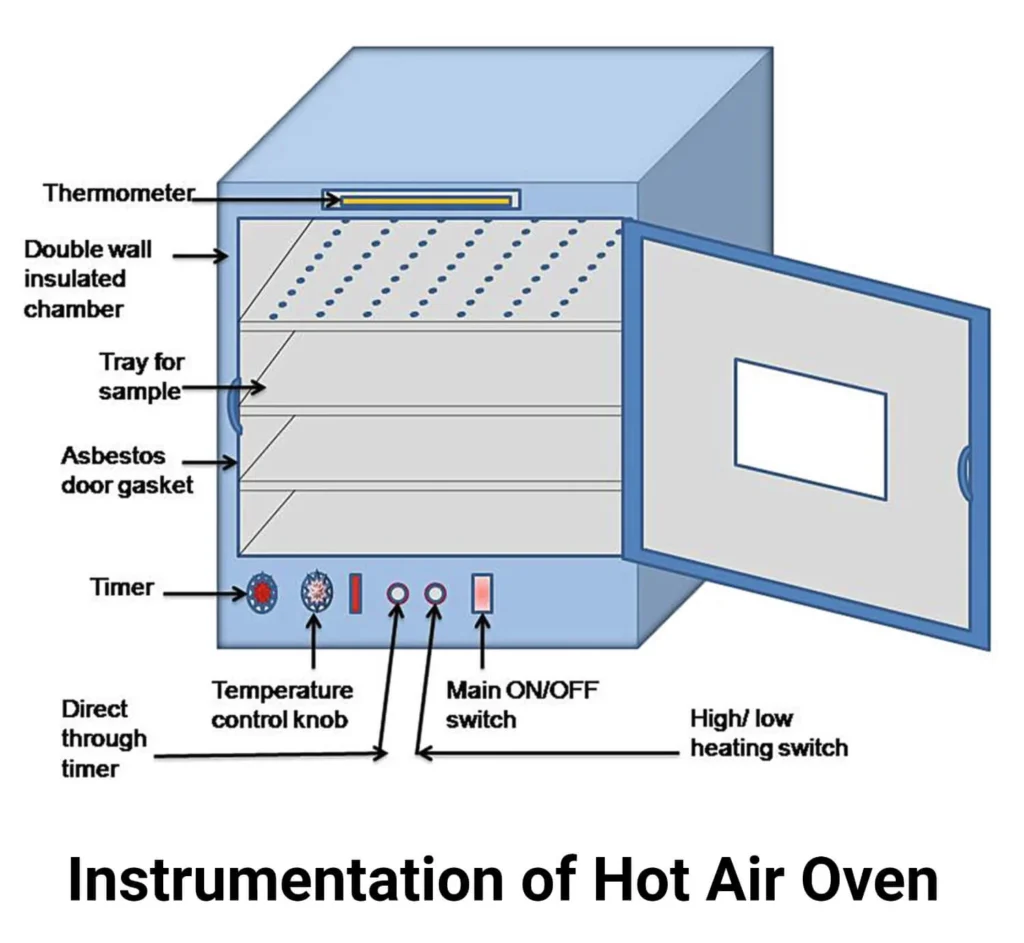

- Heating Element: Heats the air inside the oven.

- Fan: Ensures uniform temperature distribution by circulating hot air.

- Thermostat: Controls the temperature to maintain a set point.

- Insulated Chamber: Ensures minimum heat loss and smooth use of energy.

The process typically involves placing items on racks within the oven, & setting the desired temperature and duration, and allowing the oven to heat and sterilize the items.

How Forced Convection Works

Modern hot air ovens often use a motorized fan or blower for forced convection, resulting the hot air is actively pushed throughout the chamber. This ensures every part of the oven get hot air, no matter where your samples are placed receives the same steady heat. With this constant movement, items inside hot air oven dry and sterilize more quickly and reliably.

Step-by-Step Guide for Operating Hot Air Ovens

- Power on and Preheat: Plug in the oven and switch it on. Preheat for around 30 minutes so the chamber reaches the specific temperature before loading items.

- Set Temperature and Time: Use the temperature gauge or thermostat to set the required temperature and holding time, depending on the load size and type of material.

- Load Items Properly: Place the items on the trays or racks, ensuring you leave enough space between them for proper air circulation. This promotes even heating and effective sterilization.

- Secure the Door: Close the door tightly and fasten any screws or locks to prevent heat loss.

- Monitor the Cycle: Periodically check the digital display to ensure the chamber has reached and maintains the set temperature for the entire holding period.

- Cooling Down: Once the cycle is complete, switch off the oven and let it cool before opening the door. This step prevents sudden temperature changes that could damage the samples or create safety hazards.

- Remove Items Safely: After cooling, carefully remove the sterilized items using oven mitts or tongs to avoid burns.

- Close the Oven: Close the door after removing your items to maintain cleanliness and prevent dust from entering.

This straightforward process ensures that everything inside the hot air oven is evenly and thoroughly sterilized, making it a reliable choice for laboratories, clinics, and industries where dry heat sterilization is essential.

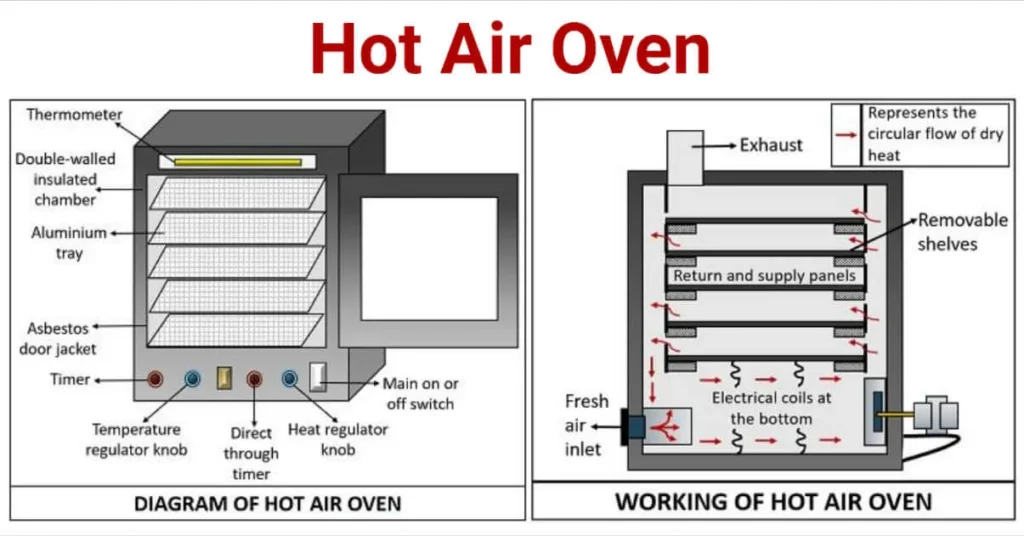

Hot Air Oven Diagram

Looking for Hot Air Oven ?

We are india based Hot Air Oven manufacturers providing 22 Litres to 600 Litres of Hot Air Ovens for all purposes, we can design and manufacture hot air ovens meeting customer provided temperature range, sizes and capacities. Connect at info@bionicsscientific.com

Principle of Hot Air Oven

Hot air oven relies on dry heat sterilization, where convection, conduction, and radiation play interlocking roles. Electrical elements warm the enclosed air, and circulating fans promote an even temperature profile throughout the chamber. Solid samples absorb this energy; the outer skin heats first, and conduction gradually routes that heat inward. In microbial cells, the rapid loss of intracellular moisture accelerates oxidative damage, denatures proteins, and raises ionic concentrations to lethal thresholds.

Instrumentation (Parts) of Hot Air Oven

A hot air oven is primarily reserved for materials that can withstand prolonged heating without melting. At uplifted temperature, the dry heat transmute proteins and thereafter eliminates pathogenic microorganisms and dormant bacterial spores. Standard dry-heat protocols include 170 C for thirty minutes, 160 C for sixty minutes, and 150 C for a full 150 minutes.

Advantages of our Hot Air Ovens

- hot air oven can kill microorganisms without the water or steam of a conventional autoclave.

- Operating costs are very modest, and the control interface typically requires little more than a start button.

- Our Hot Air Oven models reach temperatures around 180 to 250 C.

- Our compact benchtop designs occupy less space than a typical office printer and connect effortlessly to a standard wall socket.

- The workflow uses only circulating dry heat, guaranteeing that metal tools and glass slides remain completely free of rust.

- The internal chamber’s shallow depth allows researchers easy and comfortable access without any awkward maneuvers.

- Unlike autoclave cylinders, our unit generates just a few psi of overpressure, significantly minimizing any risk of explosive failure.

- We use no liquid disinfectants or volatile compounds, ensuring that no corrosive residue remains on trays after cooling.

- The uniform airflow delivers heat deeply into dense items like porcelain syringes, confidently achieving lethal temperatures on every interior surface.

Limitations of Hot Air Oven

Hot air ovens have many good points, but they also have some limitations that make them less suitable for certain types of sterilization.

- Not Suitable for All Materials: Hot air ovens can’t be used for items made of rubber, most plastics, or surgical dressings because the dry heat can cause these materials to melt, warp, or get damaged. For these items, using an autoclave or chemical disinfectants is a safer choice.

- Some Germs Are Hard to Kill: Dry heat doesn’t kill all germs equally well. Some tough bacteria and harmful proteins called prions can survive a normal hot air oven cycle. Since there is no steam or pressure, hot air ovens are not always as reliable as moist-heat methods in killing all microbes.

- Takes More Time: Hot air ovens need longer to reach the right temperatures and keep them there. This means sterilizing with hot air often takes several hours, which is slower than steam sterilizers, open flames, UV light, or chemical disinfectants. So, if you need fast results, hot air ovens might slow you down.

In short, hot air ovens work very well for sterilizing glassware, metal tools, and ceramics. But because of their limits, they can’t replace other sterilization methods when speed or handling different materials is important.

Types of Hot Air Ovens and Their Distinctions

All hot air ovens use dry heat to sterilize, but they differ in how they move air inside. This makes each type better suited for certain materials and tasks:

- Natural Convection (Gravity Convection) Ovens: These ovens work by letting hot air rise and cool air fall naturally. The heating element warms the air at the bottom, which rises, cools near the top, and then sinks again. This movement creates a slow, gentle air circulation without fans. Because the air moves slowly, the temperature inside may not be perfectly even. These ovens are best suited for heat-resistant powders or items that don’t require precise temperature control.

- Forced Convection Ovens: These ovens have a fan that pushes air around quickly and evenly inside the chamber. The strong airflow makes sure the heat spreads uniformly, so all parts of the oven reach the right temperature fast.

- Side Draught Ovens: These ovens push air from one side of the chamber straight across to the other side. This focused airflow heats items quickly, making it ideal for fast processes like warming plastic medical clothing in hospitals or preheating sheets and plates in industries.

Choosing the right hot air oven depends on what you need—whether it’s even heating, speed, or a simple oven for heat-resistant materials. Each type offers useful advantages for different sterilization jobs.

Looking for Hot Air Oven ?

We are India-based manufacturers of Hot Air Ovens, providing models with capacities ranging from 22 Litres to 600 Litres for various purposes. We can design and manufacture hot air ovens meeting the customer-provided temperature range, sizes, and capacities. Connect at info@bionicsscientific.com

Bionics HOT AIR OVEN Dimensions

| Model No. | Inner Chamber (W x D x H) |

Volume (Liters) |

Load (KW) |

Shelves (No’s) |

|---|---|---|---|---|

| BST/HAO-1122 | 300 x 300 x 300 mm | 30 | 1.5 | 2 |

| BST/HAO-1123 | 355 x 355 x 355 mm | 45 | 1.5 | 2 |

| BST/HAO-1124 | 455 x 455 x 455 mm | 95 | 2.0 | 2 |

| BST/HAO-1125 | 455 x 455 x 605 mm | 125 | 2.2 | 3 |

| BST/HAO-1126 | 605 x 605 x 605 mm | 224 | 2.5 | 3 |

| BST/HAO-1127 | 605 x 455 x 910 mm | 252 | 2.5 | 3 |

| BST/HAO-1128 | 605 x 605 x 910 mm | 336 | 3.0 | 3 |

Key Points:

- Sterilization Method: Dry heat (not moisture-based like autoclaves).

- Standard Temperature: 160°C for 2 hours or 180°C for 30 minutes.

- Applications: Glassware, metal instruments, powders, and oil-based substances.

Precautions When Using a Hot Air Oven

To ensure both safety and effective sterilization, it’s important to follow some key precautions whenever you’re operating a hot air oven:

- Use Only Suitable Materials: Confirm that everything placed inside is compatible with dry heat sterilization avoid materials that can melt, ignite, or degrade at high temperatures. Never place combustible or flammable items in the oven.

- Prepare Items Appropriately: Wrap instruments, glassware, or pipettes in paper or suitable wrapping before loading them into metal or heat-resistant containers. Cotton wool plugs are commonly used to protect the mouths of test tubes and flasks during sterilization.

- Allow Cooling Time: It’s tempting to get your hands on those freshly-sterilized beakers right away, but always let the oven cool to at least 40°C before opening the door. Opening too soon can cause temperature shocks, potentially cracking glassware.

- Handle with Care: When unloading, use thermal gloves or tongs, not bare hands, to prevent burns and accidental drops.

- Avoid Overcrowding: Give your items some breathing room. Overloading shelves restricts the circulation of hot air, so space items evenly for consistent results.

- Proper Arrangement: Ensure objects have enough space between them on the shelves to allow hot air to circulate freely around every surface.

By keeping these best practices in mind, you’ll protect both your lab equipment and yourself while maximizing the sterilization efficiency of the oven.

Applications of Hot Air Ovens

Hot air ovens are used in various fields for different purposes:

- Medical: Sterilizing surgical instruments, glassware, and other medical tools.

- Laboratory: Drying samples, sterilizing equipment, and preparing materials.

- Industrial: Curing paints and coatings, drying materials, and heat-treating products.

For example, in a medical setting, a hot air oven might be used to ensure that surgical instruments are free of any viable microorganisms before use in procedures.

Benefits of Using a Hot Air Oven

- Efficiency: Hot air ovens can handle large volumes of items, making them ideal for high-volume settings.

- Safety: Dry heat sterilization is a reliable method that doesn’t involve moisture, reducing the risk of rust and corrosion.

- Versatility: They can be used for a wide range of applications, from sterilizing equipment to curing industrial materials.

Maintenance and Best Practices

Proper maintenance ensures the optimal performance of hot air ovens:

- Regular Cleaning: Clean the chamber and racks regularly to prevent contamination.

- Routine Inspections: Check the heating element, fan, and thermostat for any signs of wear or damage.

- Calibration: Ensure the thermostat is accurately calibrated for precise temperature control.

- Troubleshooting: Address common issues such as uneven heating or temperature fluctuations promptly to maintain efficiency.

How a Hot Air Oven Gets the Job Done

Think of a hot air oven as a super-powered, high-precision conventional oven. Its main job is to sterilize items using dry heat. The basic principle is convection—electric coils inside the oven heat up, and a fan circulates the hot air all around the chamber. This constant airflow ensures there are no cold spots and that every surface of the items inside gets blasted with uniform heat.

You’ll find these essential machines in all sorts of scientific and medical settings, from microbiology labs and hospitals to pharmaceutical companies.

The Sterilization Process: Time and Temperature

Hot air ovens can operate over a wide temperature range, typically from 50°C to 300°C (122°F to 572°F). The key advantage of using dry heat is that it sterilizes materials without any moisture, which is crucial for items that could be damaged by steam, like sharp metal instruments that might rust or powders that would clump.

The rule of thumb is: the hotter the temperature, the shorter the time needed. The most common sterilization cycles are:

- 160°C (320°F) for 2 hours

- 170°C (338°F) for 1 hour

- 180°C (356°F) for 30 minutes

The exact time depends on what you’re sterilizing and how much you’ve packed into the oven.

What Can (and Can’t) Go in the Oven?

A hot air oven is perfect for sterilizing things that can withstand high temperatures but are sensitive to moisture. This includes:

- Glassware (like flasks, beakers, and pipettes)

- Metal instruments (like forceps and scalpels)

- Powders, oils, and waxes that are heat-stable

On the other hand, you should never put things like plastic, rubber, or most fabrics in a hot air oven, as they can melt, char, or be destroyed.

This is the main difference between a hot air oven and an autoclave. An autoclave uses pressurized steam (moist heat) to sterilize, which works at a lower temperature and for a shorter time. While an oven is great for glassware and powders, an autoclave is the go-to for liquids, surgical tools, and fabrics. Think of it as the difference between baking (dry heat) and pressure cooking (moist heat).

Staying Safe and Keeping It Maintained

Working with such high temperatures requires caution. Always follow these safety rules:

- Never open the oven door while it’s in the middle of a cycle.

- Always wear heat-resistant gloves when loading or unloading items.

- Let everything cool down completely before you try to handle it.

- Periodically check that the oven’s temperature display is accurate.

To keep your oven in great shape, just a little routine maintenance is needed. Make sure to clean the inside chamber regularly, check that the fan and vents aren’t blocked, and inspect the door seal to make sure it’s tight. It’s also a good idea to have it professionally serviced once a year to ensure it’s working accurately and safely.

How Does a Natural or Gravity Convection Oven Work?

Natural convection, or gravity convection ovens, heat using the simple movement of air—no built-in fans required. As the heating element warms the air inside the chamber, that hot air naturally rises to the top because it’s less dense. Cooler air then drifts downwards to replace it, creating a continuous cycle as the air gradually circulates.

This method results in slower, less uniform heat distribution compared to forced-air models. Still, it’s gentle and highly effective for materials that might be disturbed by airflow, such as powders and lightweight samples. Gravity convection ovens are a solid choice in labs and industries where delicate, consistent heat without drafts is more important than absolute temperature uniformity.

Side Draught Oven: Operation and Typical Uses

A side draught oven introduces air from one side of the chamber and allows it to pass directly across the contents to the opposite side, creating a steady, one-way current. This targeted airflow ensures that every item inside receives consistent heat exposure, making the process efficient and uniform.

This design is instrumental when rapid or thorough heating is required. Commonly, side draught ovens are used in hospital settings for preheating items like plastic aprons or sterilizing flat materials such as sheets and metal plates. The unidirectional flow helps maximize heat transfer and minimizes the time needed to reach sterilization or drying targets, making these ovens ideal for tasks that demand quick and even results.

What is a hot air oven used for?

A hot air oven is generally used for sterilizing laboratory glassware, instruments, and powders. It works on the basis of dry heat at high temperatures, which effectively destroys bacteria and microorganisms.

How does a hot air oven work?

A hot air oven works on the principle of convection. Electric heating elements generate heat, and a fan circulates the hot air evenly inside the chamber. Uniform heat exposure ensures proper sterilization of all items.

What is the basic temperature range of a hot air oven?

Most hot air ovens operate between 50°C and 300 300°C. Sterilization is generally carried out at 160–180°C for specific durations, depending on the type of material.

What materials can be sterilized in a hot air oven?

Items that can withstand dry heat are sterilized in hot air ovens. These include glassware (beakers, flasks, pipettes), metal instruments, powders, and oils. Plastic, rubber, and fabric materials are not suitable.

What is the difference between a hot air oven and an autoclave?

Hot air oven: Uses dry heat, higher temperature, and longer time.

Autoclave: Uses steam under pressure, lower temperature, shorter time.

Hot air ovens are ideal for glassware and powders, while autoclaves suit liquids, fabrics, and surgical tools.

Why is dry heat sterilization necessary in laboratories?

Dry heat sterilization prevents corrosion, moisture damage, or residue left on materials. This makes it crucial for powders, oils, and sharp metal instruments that can be damaged by steam sterilization.

What safety precautions should be taken when using a hot air oven?

Avoid opening the door during operation.

Use heat-resistant gloves while handling items.

Allow cooling before removing materials.

Regularly check the temperature calibration for accuracy.

How do you maintain a hot air oven?

Routine maintenance includes:

Cleaning the chamber regularly.

Ensuring the fan and vents are not blocked.

Checking door seals for proper insulation.

Annual professional servicing to verify heating accuracy.

Where are hot air ovens generally used?

They are widely used in microbiology labs, pharmaceutical industries, hospitals, and research institutes. Any place requiring sterilization of dry items relies on hot air ovens.

Conclusion

Hot Air ovens are important equipment in various industries, providing a reliable and efficient method for material heating and drying. Their ability to maintain stable temperatures and handle large amounts of material make them indispensable in medical, laboratory and industrial environments. How they work and taking proper care of them is essential in maintaining the highest hygiene and safety standards. In this hot air oven video, we have explained the manufacturing process of Hot Air Ovens