In research and industrial testing, accuracy means everything. One unsung hero behind this precision is the muffle furnace which is a high temperature lab furnace designed to deliver clean and consistent heating.

Although it may look like a simple insulated box but it plays a key role in material analysis, chemical testing and quality control. Wherever extreme heat and reliability are needed thats where a muffle furnace comes into preference and ensures dependable performance.

- The Core Technology: What is Under the Hood of a Muffle Furnace?

- Main Components That Drive Muffle Furnace Performance

- Important Applications of Muffle Furnaces: Where Precision Meets Practice

- Navigating the Market: A Guide to Muffle Furnace Manufacturers

- Bionics Scientific: Your Go To, Value Driven Supplier for Muffle Furnaces

- Conclusion: Investing in Precision with the Right Muffle Furnace

- Muffle Furnace Video

- Frequently Asked Questions: Muffle Furnace FAQs

- What is a muffle furnace and how is it different from a regular lab oven?

- What are the most common applications for a muffle furnace?

- What does the muffle in a muffle furnace actually mean?

- What are the most important factors to consider when buying a muffle furnace?

- Who are some well known muffle furnace manufacturers?

- What is a crucible and why is it important?

- What exactly does a thermocouple do in a muffle furnace?

But here’s the catch: Ever walk into the market to buy a muffle furnace and suddenly it feels like stepping into a maze. Dozens of models, heaps of jargon and prices that jump from budget friendly to sky high. So how do you know which muffle furnace really gives the best value?Thats exactly what this guide is here for.

Whether you’re a lab manager setting up new infrastructure, a researcher chasing precision in every experiment or a technician ensuring daily consistency, we have got you covered.

In the next few minutes, we will unpack the real science behind muffle furnaces that how they work, what makes one model better than another and what hidden features can actually save you time and resources.

By the end, you will not only understand the technology that drives these high temperature marvels but you will also know how to choose one that fits into the lab perfectly technically, practically and financially.

The Core Technology: What is Under the Hood of a Muffle Furnace?

Before selecting the right furnace, its essential to grasp its fundamental design and the components that dictate performance. At its simplest, an electric muffle furnace functions like an oven which uses resistive heating elements to generate high temperatures.

indirect heating method is the furnace’s key advantage, ensuring that samples remain contamination free even as the heating elements age or degrade.

A common misconception is calling it a furnace muffler. The term muffle does not mean silencing. Rather, it reflects the furnace ability to wrap or isolate the sample which keeps it safe from unwanted impurities while achieving precise and uniform heat.

Bionics Scientific stands for excellence. We deliver high-performance, ISO and CE certified laboratory equipment engineered for precision and durability. Trusted by researchers worldwide, we are your dedicated partner in scientific innovation.

Main Components That Drive Muffle Furnace Performance

A muffle furnace that hits temperatures over 1500°C is seriously powerful but its performance depends on what is inside. To understand it we need to take a closer look at the main parts that make it work so well.

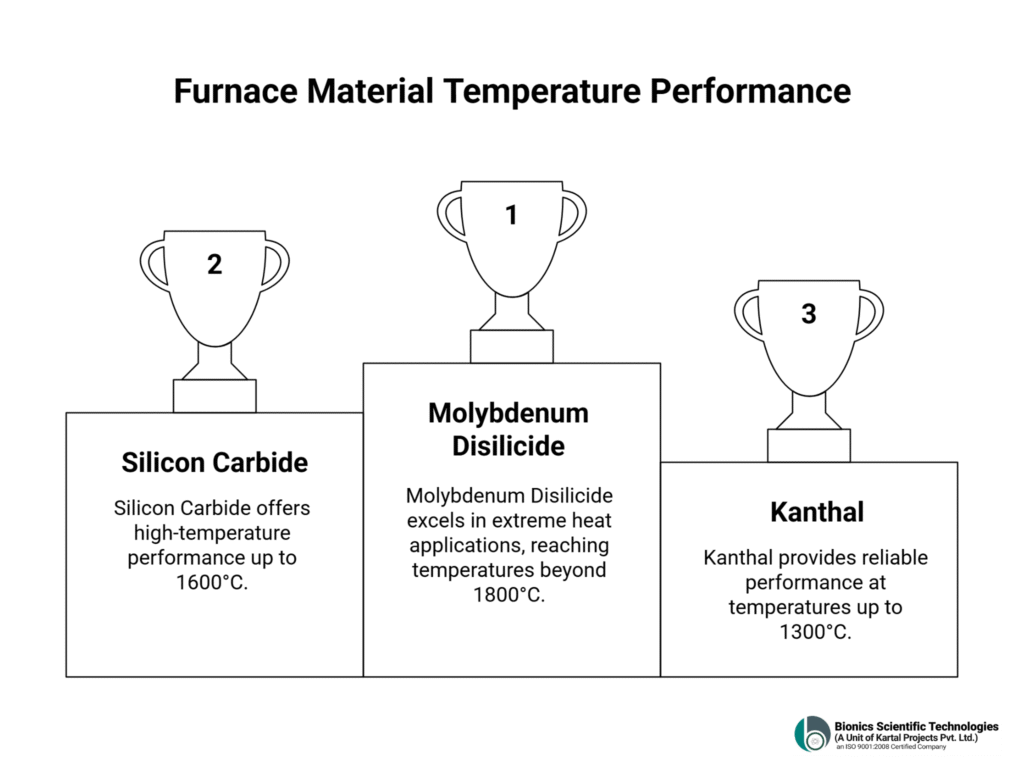

1. Heating Elements

These are the furnaces powerhouse. The material chosen directly affects how hot the furnace can get and how long it will remain.

- Kanthal: A durable Iron Chromium and Aluminum alloy that performs reliably at temperatures up to 1300°C

- Silicon Carbide: Up to 1600°C

- Molybdenum Disilicide: For extreme applications beyond 1800°C

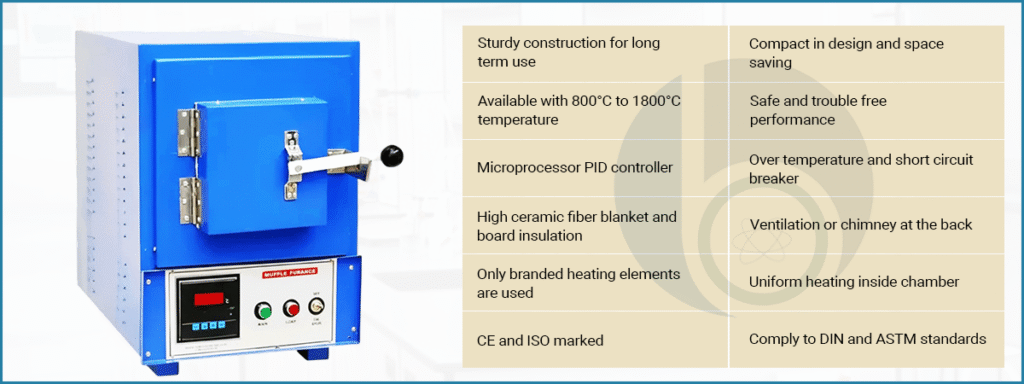

2. Insulation

Efficient insulation ensures high temperatures reaches quickly and maintain consistently without wasting energy. Modern furnaces use lightweight ceramic fiber insulation which heats and cools faster than traditional heavy firebrick designs.

3. Thermocouple : Temperature Sensor

The thermocouple acts as the furnaces nervous system which provides real time temperature readings to the controller. Accuracy here is critical:

- Type K: General laboratory use

- Type S or B: Required for higher temperature ranges

Regular calibration helps keep results accurate and consistent every time.

4. Crucible : Sample Vessel

The crucible must withstand extreme temperatures without reacting with the sample. Common materials include:

- Porcelain for lower temperature ashing

- High purity alumina or quartz for more demanding chemical tests

- Platinum for ultra critical applications

5. Temperature Controller

Modern muffle furnaces use programmable PID controllers. These allow users to create complex heating profiles with multiple steps, ramps known as rate of temperature change and dwells also called as holding at a specific temperature giving unmatched control and repeatability.

Understanding how these parts work together helps different basic furnaces from high performance machines designed for critical scientific and industrial applications.

Searching for a reliable Muffle Furnace that is both ISO 9001 and CE certified?

Explore the certified range from Bionics Scientific. Our Muffle Furnace are the go-to choice for labs where accuracy, excellent separation efficiency, and repeatable results are non-negotiable. Contact our experts at info@bionicsscientific.com or call +91 9111161955 | 9376651333.

Important Applications of Muffle Furnaces: Where Precision Meets Practice

A muffle furnace is not just a high temperature oven but in fact its a versatile mechanism that powers countless laboratory and industrial processes. Here is where it really shines:

1. Material Testing and Research

From ceramics to metals and composites the researchers rely on muffle furnaces to study material properties. Controlled heating ensures consistent results whether you are testing thermal stability, hardness or ash content.

2. Ash Content Analysis

In food, pharmaceuticals and fuel industries,to determine the ash content of a sample is critical. Muffle furnaces provide clean, uniform heating and ensure accurate gravimetric measurements without contamination.

3. Heat Treatment and Sintering

For metallurgy and ceramics the muffle furnaces delivers the extreme temperatures necessary for sintering powders or heat treating metals which enhance strength plus durability and structural integrity.

4. Chemical Decomposition and Calcination

In chemical labs, muffle furnaces help break down compounds, remove volatile components or calcine materials all under a controlled and contamination free environment.

5. Quality Control in Industrial Processes

From rubber and plastics to cement and coal testing, generally the industries depend on muffle furnaces to maintain consistent quality, verify composition and ensure standard compliances.

In short, any process that demands high temperatures, precision and cleanliness can drive it from a muffle furnace. Understanding its applications helps buyers match the right furnace to the right task which ensures both accuracy and efficiency in the lab or production line.

Navigating the Market: A Guide to Muffle Furnace Manufacturers

Once after understanding the technology and its applications, the next step is selecting the right muffle furnace for lab or industrial needs.

Prices vary widely from a few thousand dollars for a compact, basic unit to tens of thousands for large and high temperature programmable models.The key is matching the furnace’s capabilities to specific requirements rather than simply choosing the most expensive option.

The market is totally occupied with reliable and well established muffle furnace manufacturers with each offering a range of models designed for different temperatures, capacities and applications. Researching these manufacturers with comparing their features and understanding warranty, service support and calibration options are critical steps in making a sound investment.

By carefully considering both technical specifications and supplier credibility, the one can ensure that chosen muffle furnace delivers precision, durability and long term value.

Bionics Scientific: Your Go To, Value Driven Supplier for Muffle Furnaces

When it comes to equipping your lab, a trusted supplier can make all the difference. Bionics Scientific stands out by offering reliable, high quality and budget friendly solutions. Here is why labs love working with Bionics:

- Wider Selection of Muffle Furnaces: From small to compact units with high temperature and programmable models the Bionics have a furnace for every need.

- Top Quality Equipment: All furnaces meet standards which ensures precision, durability and consistent results.

- Budget Friendly Options: Get the features need without breaking the bank. High performance does not requires a high price tag.

- Expert Guidance: Not sure which furnace is right for which lab. Bionics team helps in choosing the perfect model for lab requirements.

- Comprehensive Support: From delivery to installation and after sales service, Bionics Scientific ensures that the clients are fully supported at every step of the way.

Partnering with Bionics Scientific means more than just buying a furnace even its more about making a smart investment in quality, reliability and long term lab success.

Conclusion: Investing in Precision with the Right Muffle Furnace

A muffle furnace is not just the another heat source in the lab but it is the quiet workhorse behind so many experiments and quality tests. It helps researchers get clean, accurate results by providing a steady and high temperature environment without any contamination. Thanks to its smart design and insulated chamber, it does the tough jobs that regular ovens simply can not handle.

When you are picking one for lab or thinking it for a long term. The right furnace can make work easier and results more reliable for years. Here is what really matters:

- Temperature range: Make sure the furnace can handle the heat levels that the experiments require.

- Control and Accuracy: With PID controllers and programmable settings, the one can easily adjust and hold the exact temperature which is needed for the best results.

- Trusted brands: Go with renown and trustworthy names such as Thermolyne, Thermo Fisher, Nabertherm or either Carbolite because they have built their reputation on quality.

- Smart suppliers: For labs looking for dependable results without overspending, Bionics Scientific is a smart pick. They offer good furnaces with proper support and fair pricing.

Buying a good muffle furnace is not just another purchase but its an addition of asset investment in the labs for accuracy and consistency. Choosing the right muffle furnace will keep experiments running smoothly for years.

Muffle Furnace Video

Frequently Asked Questions: Muffle Furnace FAQs

What is a muffle furnace and how is it different from a regular lab oven?

A muffle furnace is simply a high temperature version of a lab oven which is designed to heat samples without letting them touch the heating elements directly. The key difference is the muffle is an insulated inner chamber that keeps the samples separated from the heating coils. This setup keeps things clean also avoids contamination and lets the furnace reach extreme temperatures often well above 1000°C which is far beyond what a regular oven can handle.

What are the most common applications for a muffle furnace?

Muffle furnaces are incredibly handy for all sorts of high temperature work in labs and industries. They are used to burn off organic material to measure ash content, strengthen metals and ceramics through heat treating, fuse powdered materials into solid pieces and get accurate measurements by heating samples to a stable weight and test how new materials handle extreme heat. Despite looking like a simple oven, the muffle furnace are a powerful tool that keeps experiments accurate and reliable.

What does the muffle in a muffle furnace actually mean?

The muffle is a small chamber made of high temperature ceramic materials. It keeps the sample separate from the heating elements and in turn makes sure it heats evenly and stays clean.

What are the most important factors to consider when buying a muffle furnace?

Maximum Temperature: Make sure it reaches the temperatures which the desire applications require.

Chamber Volume: Select a size that fits sample workload easily.

Temperature Controller: Simple single setpoint vs. multi stage programmable controllers.

Price and Durability: Balance budget with reliability for long term use.

Who are some well known muffle furnace manufacturers?

Trusted brands like Thermolyne, Thermo Scientific and Nabertherm and Carbolite Gero. Reputable suppliers like Bionics Scientific also provide a wider range of models.

What is a crucible and why is it important?

A crucible is basically a small cup made of ceramic or metal that holds samples in the furnace. It has to survive the heat without cracking or reacting with whats there inside. Using the right one keeps results accurate and work safest.

What exactly does a thermocouple do in a muffle furnace?

A thermocouple is like the furnaces temperature monitor. It sits inside the chamber which keeps a close eye on the heat level. The moment there is even a small change, it signals the controller which adjusts the power going to the heating elements. This back and forth process keeps the temperature steady pus accurate and right on target for every experiment.

Searching for a reliable Muffle Furnace that is both ISO 9001 and CE certified?

Explore the certified range from Bionics Scientific. Our Muffle Furnace are the go-to choice for labs where accuracy, excellent separation efficiency, and repeatable results are non-negotiable. Contact our experts at info@bionicsscientific.com or call +91 9111161955 | 9376651333.