Salt Spray Test Chambers Manufacturing at Bionics Scientific Technologies, Corrosion has become one of the most common and costly challenge industry which is being faced today universally.

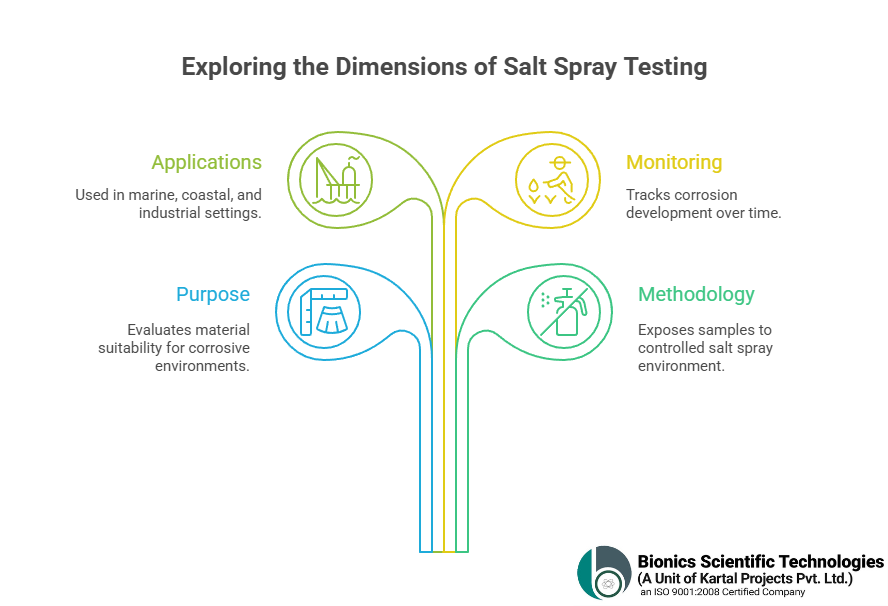

From car parts to marine gear and protective coatings, humidity in the atmosphere and salty conditions can take a toll on materials. To make sure products hold up over time, manufacturers rely on salt spray testing to check how well they resist rust and corrosion.

- Understanding Salt Spray Corrosion Test Chambers and Their Importance

- The Secret Behind Reliable, Rust Free Product

- Salt Spray Test Methods and Industry Standards for Reliable Durability

- Different Types of Salt Spray Testing for Reliable Corrosion Protection

- Salt Spray Chamber Design and Features for Effective Corrosion Testing

- Salt Spray Test Parameters and Setup Guide

- Salt Spray Chamber Maintenance and Safety Tips

- Tips for Choosing the Right Salt Spray Corrosion Test Chamber

- Conclusion: Choosing and Using Salt Spray Chambers Effectively

Let’s dive into the deeper mechanism of what a Salt Spray Test Chamber is, why it is used and what testing standards it follows and which features to look for when choosing one? Let’s understand it one by one!

Understanding Salt Spray Corrosion Test Chambers and Their Importance

- Simple definition: A salt spray chamber is a laboratory device used to speed up the process of corrosion testing.

- How it works: Inside the chamber, a fine mist of salt solution, usually 5% sodium chloride is sprayed to create harsh and real world conditions.

- What goes inside the chamber : Items like coated metals, painted surfaces and plated parts are tested to see how they handle corrosion over time.

- Why it matters nowadays: This test helps manufacturers find out how strong and durable their products really are when it comes to fighting rust and corrosion.

- Main purpose: To check whether a coating or material can resist rust, blistering or surface damage over time.

- Trusted worldwide: Being one of the oldest accelerated corrosion tests, it is still widely relied on by industries all over the world.

This test shows how well a coating or material can handle rust and wear over time, giving a real sense of its durability. It is one of the oldest and most trusted accelerated corrosion tests which is widely used across industries worldwide.

The Secret Behind Reliable, Rust Free Product

Corrosion can cause serious problems such as structural failures, unexpected product recalls and expensive maintenance. By testing products under controlled salt spray conditions, manufacturers can take aid in:

- Automotive industry: Helps ensure car bodies, exhaust systems and fasteners stay protected against rust that extends vehicle life and safety.

- Marine industry: Confirms the durability of ship components, anchors and offshore structures against harsh saltwater conditions.

- Construction: Examine the durability of railings, windows and exterior coatings to ensure they can withstand outdoor exposure over the time.

- Electronics & Aerospace : Protects housings and critical components from moisture and salt which reduces the risk of failures in demanding environments.

Salt spray testing helps companies make better products along with avoiding expensive warranty issues and meeting international quality standards giving both manufacturers and customers peace of mind.

Salt Spray Test Methods and Industry Standards for Reliable Durability

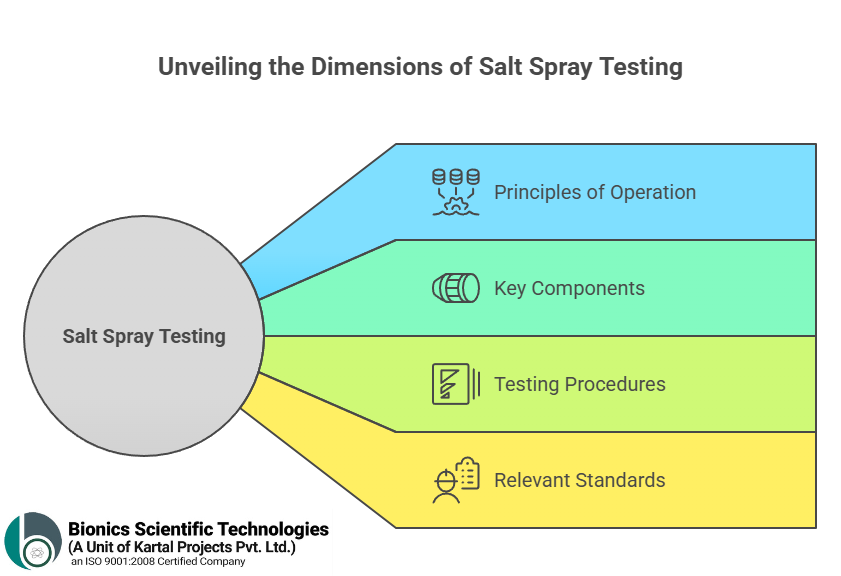

When it comes to checking how well materials resist corrosion, there are a few key standards that most manufacturers follow regularly:

- ASTM B117 :The go to standard for Neutral Salt Spray also known as NSS testing. It has been trusted for years to see how well metals and coatings can withstand corrosion. It uses a 5% salt solution with a pH of 6.5 to 7.2 and keeps the chamber at a steady 35°C. It is simple but effective for seeing how coatings and metals hold up over time.

- ISO 9227 is a bit more flexible: it lets test materials using Neutral Salt Spray, Acetic Acid Salt Spray or Copper Accelerated Acetic Acid Salt Spray, so you can see how they hold up in different conditions.It is handy if you want to test materials under different corrosive conditions and really understand their durability.

- ASTM G85: This standard takes things a step further with modified, cyclic tests. It is perfect for seeing how coatings and plated parts really handle tough environments like being outdoors or out at sea.

Above these standards are not just about ticking boxes but it too helps companies make stronger and longer lasting products that perform reliably in the real world.

Different Types of Salt Spray Testing for Reliable Corrosion Protection

Neutral Salt Spray: The most common and widely used method for general corrosion testing which is ideal for evaluating basic rust resistance.

Acetic Acid Salt Spray: Often used for decorative coatings such as nickel and chromium plating that helps in checking how well they maintain their appearance and protection.

Copper Accelerated Acetic Acid Salt Spray: A more aggressive version of salt spray testing which is designed for coatings that demand high levels of corrosion resistance.

Cyclic Corrosion Testing: Alternates between salt spray, drying and humidity cycles to closely simulate real world outdoor conditions which gives a more accurate measure of long term durability

Salt Spray Chamber Design and Features for Effective Corrosion Testing

A good salt spray chamber is not just a box that sprays salt In fact it is carefully designed to give accurate and reliable results. Here are the main features that make a difference:

- Durable Construction : Made from strong and corrosion resistant materials.These chambers are built to last also standing up to the harsh conditions inside without wearing down.

- Reliable Fog System: A continuous and gentle mist covers all the samples evenly which gives a true picture of how they hold up over time.

- Precise Temperature and Humidity Control: By keeping temperature and humidity steady the chamber ensures test results are consistent and dependable.

- Tight Sealing and Insulation : Proper sealing keeps everything contained inside the chamber which protects the test from outside interference and ensures accurate results.

- Thoughtful Sample Racks and Holders: Designed so the mist reaches every surface of the items being tested which gives a true picture of durability.

- Observation Window: A viewing port lets manufacturers check on tests without disturbing the controlled environment inside the chamber.

Salt Spray Test Parameters and Setup Guide

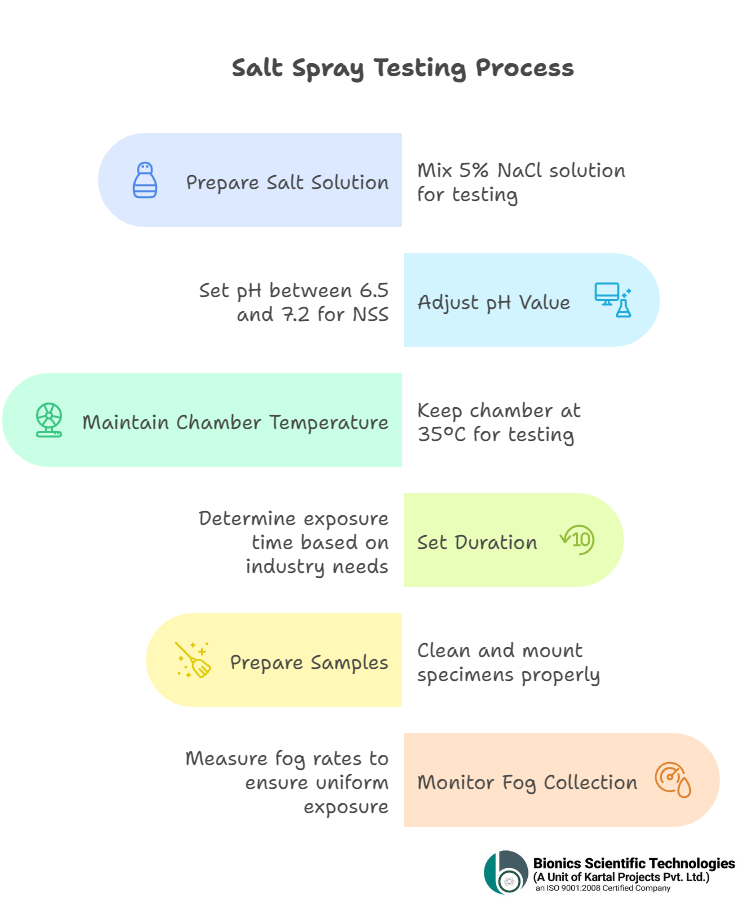

Salt spray testing requires careful attention to detail:

- Salt solution concentration: usually 5% NaCl for NSS testing.

- pH value: between 6.5 and 7.2 for neutral salt spray and it can be adjusted lower for AASS or CASS.

- Chamber temperature: generally maintained at 35°C.

- Duration: exposure times can range from 24 hours to 1000 plus hours and it too depends on industry requirements.

- Sample preparation: specimens should be cleaned, degreased and properly mounted at an angle.

- Monitoring: fog collection rates are measured to ensure uniform exposure.

Salt Spray Chamber Maintenance and Safety Tips

Keeping a salt spray chamber in good shape is not complicated. It is really just about a little regular care. Think of it like looking after a trusted tool that helps get reliable results every time.

- Keep things clean: Give the nozzles, reservoir and chamber walls a wipe now and then. Salt buildup might seem harmless but it can mess with the test results.

- Check your instruments: Make sure the temperature sensors, pH meters and fog collection devices are all calibrated. It keeps everything accurate and consistent.

- Use the right water: Stick with distilled water when mixing the salt solution. It avoids the impurities and keeps tests on point.

- Ventilation matters: Good airflow keeps the corrosive mist under control and makes the workspace safer and more reliable for testing.

- Protection : Gloves, goggles and protective clothing are a must. Safety comes first.

Tips for Choosing the Right Salt Spray Corrosion Test Chamber

Before buying a salt spray chamber, it helps to think through a few key points:

- What is being tested : Are the samples painted, electroplated parts or advanced coatings? Knowing this helps narrow down the options.

- Type of tests needed: Will it just be Neutral Salt Spray or do you also want to run AASS, CASS or cyclic corrosion tests? Getting a chamber that can handle it all from the start makes life so much easier.

- Size consideration : Making sure the chamber is big enough for all samples, both in size and quantity.

- Compliances and Standards : Look for chambers that meet ASTM, ISO or other relevant standards. It keeps testing reliable and widely accepted.

- Ease of use:Having a simple interface, automated controls and safety features takes the stress out of testing and saves a lot of time.

- Support and service :It helps a lot to have a supplier who provides spare parts, calibration, and support having that backup can save a lot of headaches later.

Choosing the right chamber means tests are accurate and it helps avoid costly problems later by keeping products from wearing out too quickly.

Frequently Asked Questions About Salt Spray Chambers:

Q1: What is the ultimate use of a Salt Spray Corrosion Test Chamber?

A: A salt spray corrosion test chamber is used to see how well materials, coatings and metals can bear the rust and corrosion. By creating a controlled salty, humid environment it fosters testing so manufacturers can see how durable a product will be when it is put into use.

Q2: What kind of industries use salt spray testing the most?

A: Industries like automotive followed by aerospace and marine as well as construction, defense and electronics all rely on salt spray testing for accurate control and certification.

Q3: What is the general difference between neutral salt spray and cyclic corrosion

A: With NSS,materials are exposed to a constant salt fog. CCT, on the other hand switches between fog, humidity and drying that gives a more realistic look at how products hold up outside.

Q4: How long does a standard salt spray test can last?

A: It all depends on the standard and the type of coating.Usually durations range from 24 hours to 96 to 240 to 500 or even 1000 hours.

Q5: Which standards define salt spray testing methods best?

A: The most commonly used standards are ASTM B117 as well as ISO 9227 and ASTM G85. They make the rules for things like salt concentration, pH levels and temperature to make sure tests are consistent and reliable.

Q6: Does passing a salt spray test guarantee real world performance?

A: Not quite. Passing the test shows how materials perform under controlled, boosted conditions but actual performance in the field also depends on factors like weather, environment and how the material is designed.

Q7: What kind of solution goes inside the chamber?

A: For most Neutral Salt Spray generally known as NSS tests, a 5 percent sodium chloride is used. For more advanced tests like AASS or CASS additives such as acetic acid or copper chloride are included to boost harsher conditions.

Q8: How should samples be prepared before testing precisely ?

A: Samples should be cleaned also degreased and set up at the right angle so the mist touches every part. When prepared correctly the test results are much more trustworthy

Q9:What kind of maintenance does a salt spray chamber need?

A: Keeping a salt spray chamber in top shape is easier than it sounds. Just make sure to clean the nozzles, reservoir and chamber walls regularly with calibrated sensors and always use distilled water for the salt solution. A little care goes a long way in keeping the chamber reliable and the test results accurate.

Q10: How do I choose the right salt spray chamber for my lab?

A: Picking the right chamber starts with thinking about the types of tests to be run and the standards that are required to meet. Next, consider the size of the chamber that how easy it is to use also whether it meets compliance requirements and the level of support from the supplier.When cyclic corrosion testing is part of the plan alongside standard NSS with spending a little extra time choosing the right chamber upfront pays off and in turn making testing easier, more accurate and stress free down the line.

Looking for Salt Spray Test Chamber?

Bionics Scientific manufactures test chambers manufacturing where we manufacture salt spray chambers for your laboratory requirements, we are into laboratory products manufacturing since 2000, It been 25 years now, we are into laboratory products manufacturing, Connect now for a quick inquiry! Call Us: +91 9111161955, 9376651333 | Email us: info@bionicsscientific.com

Conclusion: Choosing and Using Salt Spray Chambers Effectively

A salt spray corrosion test chamber is not merely another piece of lab equipment But it is a way to see how materials and coatings will really hold up when things get tough. Stick to the right standards, set the test conditions correctly and take care of the chamber and the results you get will be reliable and meaningful.

No matter if you are working with car parts or marine equipment or surface coatings having the right salt fog test chamber makes a big difference. It helps products last longer, keeps quality high and builds trust with customers. At the end of the day, it is not just testing but in general it is about making sure your products and your brand stand strong.