Every product we use in daily life whether it is a smartphone or car parts or even food packaging constantly faces changes in temperature and humidity. Electronics items can fail in damp conditions and packaging may weaken when exposed to moisture. Thats why a humidity temperature test chamber which is also known as a temperature and humidity chamber is so important. These chambers let you recreate real world climate conditions in a controlled way which makes it easier to check a product’s durability, safety and long term performance before it ever reaches customers.

- Humidity & Temperature Test Chambers: Definition, Uses and Benefits

- Why Use a Humidity and Temperature Chamber? its benefits and applications

- How a Humidity and Temperature Test Chamber Works: Key Components and its Operation

- Humidity and Temperature Test Chambers Video

- Choosing the Right Humidity & Temperature Test Chamber

- 10 FAQs About Humidity & Temperature Test Chambers

- 1. What is the difference between steady state and cyclic humidity testing?

- 2. What humidity range do most chambers cover?

- 3. How accurate are these chambers at controlling humidity?

- 4. Can chambers handle high temperature and high humidity together?

- 5. Which standards do these tests follow?

- 6. Which industries use these chambers the most?

- 7. How to take care of a chamber?

- 8. How big should the chamber be for lab use?

- 9. How long should a humidity test last?

- 10. Do room conditions affect the test?

- Conclusion

Humidity & Temperature Test Chambers: Definition, Uses and Benefits

A humidity temperature chamber is like a mini climate room where you can set both temperature and humidity with precision. It is used to check how different materials and products react when exposed to changing conditions. For example: metals, plastics, coatings and even electronics can be tested inside to see if they stay strong, safe and reliable over time.

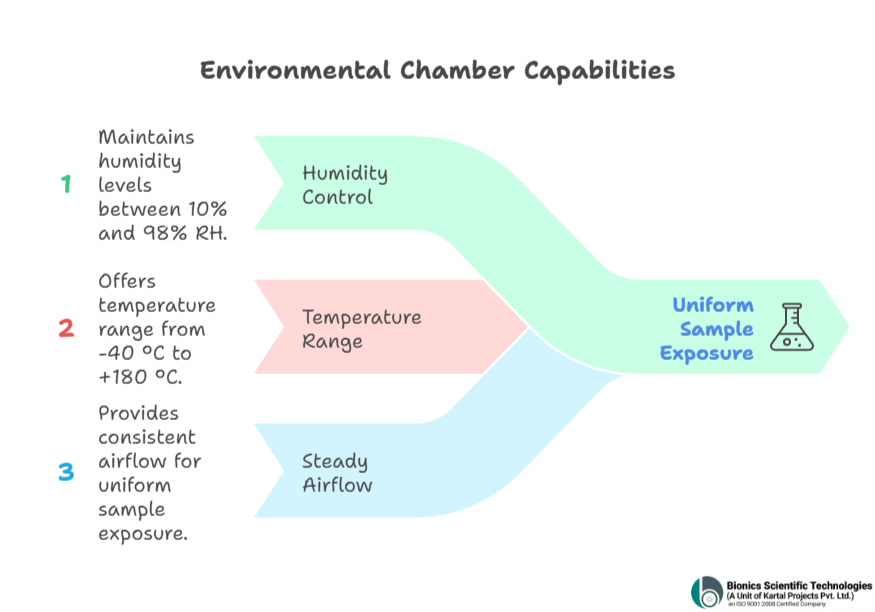

Here’s what makes these chambers so useful:

- They can control humidity from 10% to 98% RH

- The temperature range can go from as low as -40 °C up to +180 °C in advanced models

- They ensure steady airflow so every sample gets uniform exposure

- Built in accurate sensors keep conditions consistent

To narrow it down to fewer words, a humidity and temperature test chamber helps manufacturers to predict real performance before products ever reach to customers.

Why Use a Humidity and Temperature Chamber? its benefits and applications

A humidity & temperature test chamber is not just a fancy lab box but it is the ultimate product’s best friend when it comes to surviving the real world. Here’s why it matters most:

- Detect problems before they arise: Using a humidity and temperature test chamber to mark issues like corrosion, mold or moisture damage to detect them even before products reach out to customers.

- Compliances with global standards: Ensures products comply with IEC 60068, ISO and other global regulations.

- Enhance quality in industries: From electronics to automotive to aerospace to even packaging and pharmaceuticals the humidity and temperature test chamber helps in ensuring products perform reliably every time.

- Fasten aging tests: See how products hold up under extreme or changing environmental conditions in a fraction of the time.

Using a humidity and temperature chamber helps companies deliver durable, safe and high quality products all while saving time and reducing costly failures.

How a Humidity and Temperature Test Chamber Works: Key Components and its Operation

A humidity and temperature test chamber carefully controls the climate to analyse products under real conditions like:

- Temperature Control: Heaters and cooling systems usually keep the chamber at just the right temperature and so that it can adjust how quickly it heats or cools to match the test.

- Moisture Control: Humidifiers add moisture while on the other hand cooling coils remove excess with sensors keeping it slightly humidity stable.

- Airflow Management: Fans ensure even airflow avoiding hot and moist spots.

- Control and Automation: Setting up programmable test cycles and using data logging to easily monitor and keep temperature and humidity just right.

This setup ensures reliable testing for products across different industries.

Humidity and Temperature Test Chambers Video

Key points to Know for Humidity & Temperature Test Chambers

When it comes to selecting a humidity and temperature test chamber, it helps to know the basics:

- Temperature Range with Accuracy: Most chambers go from minus 40 °C to plus 180 °C and stay super precise.

- Humidity Range and Stability: Typical range goes from 10% to 95% RH and special models can reach 98% RH.

- Uniform Performance: How fast the chamber bounces back to the set conditions after opening the door or changing settings.

- Size and Capacity: From small benchtop units to reach in or even walk in chambers depends on how many samples are being tested.

- Standards and Compliances: Most follow IEC 60068 series,and some may need to meet local rules too.

Humidity & Temperature Test Chambers

Our experts can help you select the ideal Humidity & Temperature Chamber for your specific application. Contact us for a free consultation, Call: +91 911161955, 9376651133 | Email: info@bionicsscientific.com

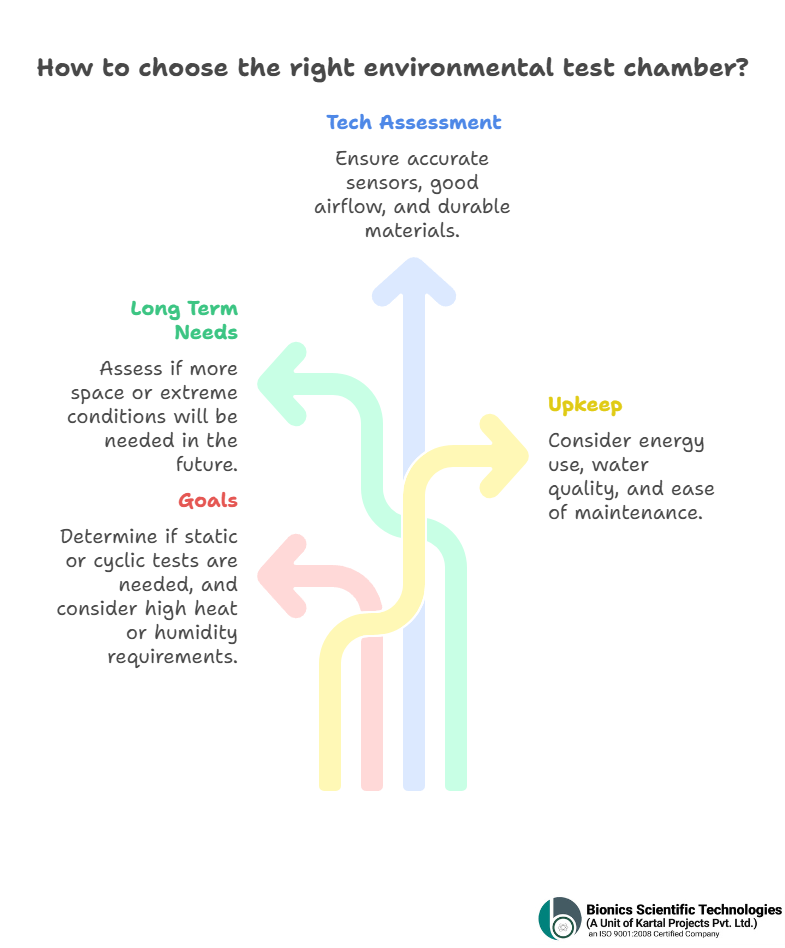

Choosing the Right Humidity & Temperature Test Chamber

Picking the right chamber does not have to be tricky. Keep these in mind:

- Know the goals: Static or cyclic tests? High heat or humidity? Fast ramp rates?

- Long term needs: Will it need more space or extreme conditions later?

- Assess the tech: Accurate sensors with good airflow and durable materials matter.

- Consider upkeep: Energy use, water quality and easy maintenance.

- Support matters: Make sure the vendor offers spare parts and reliable support.

10 FAQs About Humidity & Temperature Test Chambers

1. What is the difference between steady state and cyclic humidity testing?

Steady-state keeps the humidity and temperature constant while cyclic testing lets them change over time just like real world conditions.

2. What humidity range do most chambers cover?

Most test chambers handle between 10 percent to 95 percent RH and some special models can reach up to 98% RH.

3. How accurate are these chambers at controlling humidity?

They are usually pretty precise around ±2–3% RH depending on the sensors and calibration.

4. Can chambers handle high temperature and high humidity together?

Yes! Many chambers can maintain both at once though very extreme combinations might reduce performance a little.

5. Which standards do these tests follow?

Common ones are IEC 60068 various ISO standards and sometimes local or industry specific rules.

6. Which industries use these chambers the most?

They are popular in the industries from electronics to automotive to aerospace to pharmaceuticals to packaging and materials/coatings testing.

7. How to take care of a chamber?

Keeping humidifiers clean also use good water with calibrate sensors and check seals and prevents condensation buildup.

8. How big should the chamber be for lab use?

It depends on your samples. Benchtop chambers are great for small components, while walk in models are better for large items or lots of samples.

9. How long should a humidity test last?

It depends on the goal like some tests are just a few hours while durability or stability tests can run dozens to hundreds of hours.

10. Do room conditions affect the test?

Yes, temperature and humidity in the lab can affect results but good chambers compensate with insulation, precise control and stable water systems.

Humidity & Temperature Test Chambers

Our experts can help you select the ideal Humidity & Temperature Chamber for your specific application. Contact us for a free consultation: Call: +91 911161955, 9376651133 | Email: in@bionicsscientific.com

Conclusion

A humidity and temperature test chamber helps in detecting problems before products reach the real world. Choosing one with the right RH and temperature range, accuracy, airflow, standards compliance and easy maintenance ensures reliable testing. The right chamber saves product failures with costly returns and protects reputation.