Whether you are in a lab or running an industrial setup but getting the right particle size and separating materials properly is key to quality, efficiency and smooth production. Thats where the Electromagnetic Vibrating Sieve Shaker really stand out as its a smart and reliable machine that helps to get fast, accurate and consistent results whether you are working with pharmaceuticals, chemicals, food or with construction materials.

- What is an Electromagnetic Vibrating Sieve Shaker and What does its Sieve Shaker diagram show?

- How Does an Electromagnetic Vibrating Sieve Shaker Work?

- Key Features of Electromagnetic Vibrating Sieve Shakers

- Applications of Electromagnetic Vibrating Sieve Shakers

- How to Choose the Right Sieve Shaker

- Benefits of Using an Electromagnetic Vibrating Sieve Shaker

- Future Trends of Electromagnetic Vibrating Sieve Shaker

- Electromagnetic Vibrating Sieve Shaker Machines Video

In this blog, we will break down everything you need to know about these machines. From their features and how they work to the different types and the industries that use them, we have got you covered. We will even compare them with other popular sieve shaker machines like Rotap, mechanical, gyratory and ultrasonic models and answer the common questions you probably have about prices, top brands and tips for getting the best results. By the end, you will have a clear picture of why these machines are a must have for labs and production floors alike and how they can make your work a whole lot easier.

What is an Electromagnetic Vibrating Sieve Shaker and What does its Sieve Shaker diagram show?

An electromagnetic vibrating sieve shaker is a modern instrument used to separate particles by size with speed and accuracy. Instead of bulky motors and rotating weights it uses electromagnetic forces to create smooth and controlled vibrations. These high frequency movements pass materials through a series of sieves with different mesh sizes ensuring precise separation.

The controlled vibration makes results more reliable and consistent while keeping the process quiet and efficient. Compact and energy saving, these machines have a variety of uses in laboratories and industries for particle analysis, grading and quality control across sectors like pharmaceuticals, chemicals, food and construction.

How Does an Electromagnetic Vibrating Sieve Shaker Work?

At the heart of an electromagnetic sieve shaker is a drive coil that generates a magnetic field. This field creates rapid vibrations usually between 1,000 and 5,000 cycles per minute that spread evenly across the sieve stack. The steady and high frequency motion helps fine particles move quickly through the mesh while reducing the risk of clogging.

The machine includes a simple control panel where the vibration strength and amplitude can be adjusted. With this flexibility, it handles different kinds of samples powders, granules or even wet materials while delivering clean and reliable separation every time.

Comparison with Other Sieve Shaker Types

| Sieve Shaker Type | How it works | Features | Common Applications |

| Electromagnetic Vibrating | Electromagnetic coil creates controlled vibrations | Precise control, adjustable frequency and quiet | Pharmaceuticals, chemicals and food |

| Mechanical | Motor and eccentric weights produce shaking | Simple, durable and less precise | Bulk screening, aggregates |

| Rotap | Rotating arm gives vertical and horizontal motion | Effective mechanical sorting, great for fine samples | Soil testing and sediment analysis |

| Gyratory | Circular sieve motion | Mimics manual sieving, less precise | Basic lab sieving tasks |

| Ultrasonic | Ultrasonic waves vibrate the sieve mesh | Prevents mesh clogging, perfect for ultra fine powder | Nano materials, pharma R&D |

| Wet Sieve | Water flow assists in sieving | Stops clumping, works with sticky or fine samples | Clay, minerals and wet materials |

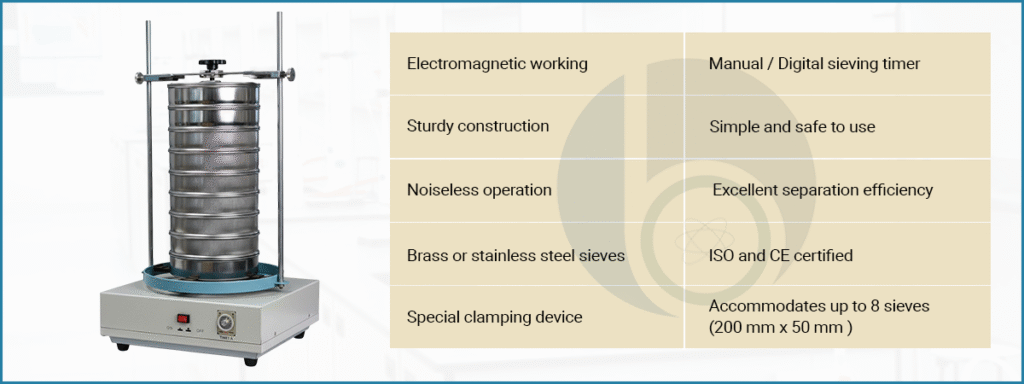

Key Features of Electromagnetic Vibrating Sieve Shakers

Here is what makes these machines so useful in labs and industries:

- Gentle but precise : High frequency and low amplitude vibrations separate particles accurately without breaking fragile materials.

- Handles more at once : Can stack 8 or more sieves together so detailed particle size analysis happens in just one run.

- Easy controls : A simple digital panel lets settings like vibration strength, time and modes be adjusted in seconds.

- Quiet worker : Runs smoothly with low noise and keeps the lab environment calm.

- Quick to set up and clean :The snap on clamps and removable sieve frames make it easy to swap or clean sieves in no time

- Made for small spaces : The compact and tabletop design is easily adjustable in labs where every inch counts.

- Works nonstop if needed : Some models even come with automation options for continuous operations.

Bionics Scientific stands for excellence. We deliver high-performance, ISO and CE certified laboratory equipment engineered for precision and durability. Trusted by researchers worldwide, we are your dedicated partner in scientific innovation.

Applications of Electromagnetic Vibrating Sieve Shakers

Electromagnetic vibrating sieve shakers are renown for their versatility used across a variety of industries:

- Pharmaceuticals : Ensures uniform particle size for drug powders which is important for consistent dosage and effectiveness.

- Food Processing : Helps grade flour to spices to sugar and other ingredients to maintain consistent product quality.

- Chemicals : Separate raw materials and intermediates by size helping reactions proceed uniformly.

- Environmental Testing : Analyzes soil sediment and sludge particles for regulatory compliance and research purposes.

- Construction & Building Materials : Classifies aggregates, sand and minerals to meet quality standards.

How to Choose the Right Sieve Shaker

Choosing a sieve shaker comes down to matching the machine with the work it needs to do:

- Know the material : Fine powders, coarse grains or wet samples all behave differently so the shaker should suit the sample type.

- Look at the workload : For small batches, a compact model works well. For bigger jobs, a machine designed for higher throughput saves time.

- Pick the style of operation : Manual shakers are straightforward but if sieving is a daily routine, an automatic option can make life easier.

- About the environment : A quieter, energy efficient unit keeps the lab comfortable and efficient.

- Durability : Easy maintenance and available spare parts mean less downtime and smoother operation.

Choosing a sieve shaker comes down to matching the machine with the work it needs to do. If you need help deciding, feel free to contact our experts.https://www.bionicsscientific.com/contact-us.php

Searching for a reliable Electromagnetic Vibrating Sieve Shaker machine that is both ISO 9001 and CE certified?

Explore the certified range from Bionics Scientific. Our sieve shakers are the go-to choice for labs where accuracy, excellent separation efficiency, and repeatable results are non-negotiable. Contact our experts at info@bionicsscientific.com or call +91 9111161955 | 9376651333.

Benefits of Using an Electromagnetic Vibrating Sieve Shaker

Electromagnetic vibrating sieve shakers come with multiple practical benefits that make them extremely useful in labs and industries:

- Faster results and less effort : Samples are processed quickly and consistently without adding strain on the operator.

- Fine tuned control : Vibration strength and settings can be adjusted to suit different materials and testing needs.

- Space friendly : Their compact and tabletop design makes them easy to fit into even small lab setups.

- One machine many uses : Handles a wide range of materials and mesh sizes that make it versatile across industries.

- Minimal energy use : Electromagnetic drives are efficient also they cut down on power consumption.

- Smoother workflows : By saving time and ensuring accuracy, they improve overall lab productivity and quality control.

Maintenance and Best Practices for Electromagnetic Vibrating Sieve Shaker

Taking good care of a sieve shaker does not take much effort but it makes a big difference in how long it lasts and how well it performs. A few habits to keep in mind are:

- Clean it often : Wipe down the sieves and the machine regularly so samples stay uncontaminated.

- Watch the mesh : Look for any signs of clogging or wear that could throw off results.

- Keep parts moving smoothly : Lubricate mechanical components when needed, following the manufacturer’s instructions.

- Check the settings : Calibrate the vibration from time to time to keep accuracy on point.

- Replace tired parts : If something looks worn out, swap it early to avoid inconsistent performance later.

Future Trends of Electromagnetic Vibrating Sieve Shaker

Sieve shakers are getting smarter. Thanks to ultrasonic technology and automated systems because of these particle separation has become simpler and more precise than ever even down to the micro and nano level. This is a game changer from industries like pharmaceuticals to nanotech to advanced materials where every tiny detail matters. Looking ahead, sieve shakers are becoming not just more accurate but also faster, easier to operate and built to meet the increasing demands of modern labs and production environments

Conclusion

The electromagnetic vibrating sieve shaker has changed the traditional way of labs and industries used to handle particle size testing earlier .It is efficient with versatile features and built to deliver consistent results. By knowing its features, different types and where it fits best that makes it easier to choose the right model for specific needs.

From pharmaceutical powders to food ingredients and industrial raw materials the electromagnetic sieve shaker ensures accurate results plus saves time and keeps processes running smoothly. In short, its a smart investment for anyone who values precision and reliability in their workflow.

Searching for a reliable Electromagnetic Vibrating Sieve Shaker machine that is both ISO 9001 and CE certified?

Explore the certified range from Bionics Scientific. Our sieve shakers are the go-to choice for labs where accuracy, excellent separation efficiency, and repeatable results are non-negotiable. Contact our experts at info@bionicsscientific.com or call +91 9111161955 | 9376651333.

Electromagnetic Vibrating Sieve Shaker Machines Video

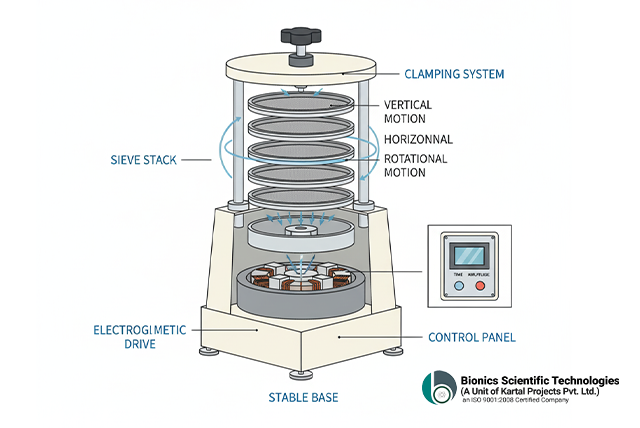

What is the Electromagnetic Vibrating Sieve Shaker Machines Principle?

The electromagnetic vibrating sieve shaker machines principle is basically based on using controlled electromagnetic vibrations to separate particles by size efficiently. The machine consists of a base with an electromagnetic drive that drives high frequency vibrations to a stack of sieves. These vibrations occur in three dimensions which are vertical, horizontal and rotational to spread the material sample evenly across all sieve layers. As a result, finer particles pass through smaller mesh openings while larger particles remain on upper sieves that ensure precise particle size separation.

This principle allows fast, accurate and consistent sieving suitable for dry and wet materials and making it ideal for industries from pharmaceuticals to food processing to chemicals. The digital control of vibration intensity and sieving duration guarantees reliable, repeatable results, increasing efficiency and quality control.

For high-quality Electromagnetic Vibrating Sieve Shaker Machines operating on this principle, Bionics Scientific Technologies, a leading manufacturer and supplier based in Delhi, India, can meet your needs. We supply all of our laboratory equipment throughout India and the worlds. You can visit our website for more information.