Trade Mark No.: 2022609

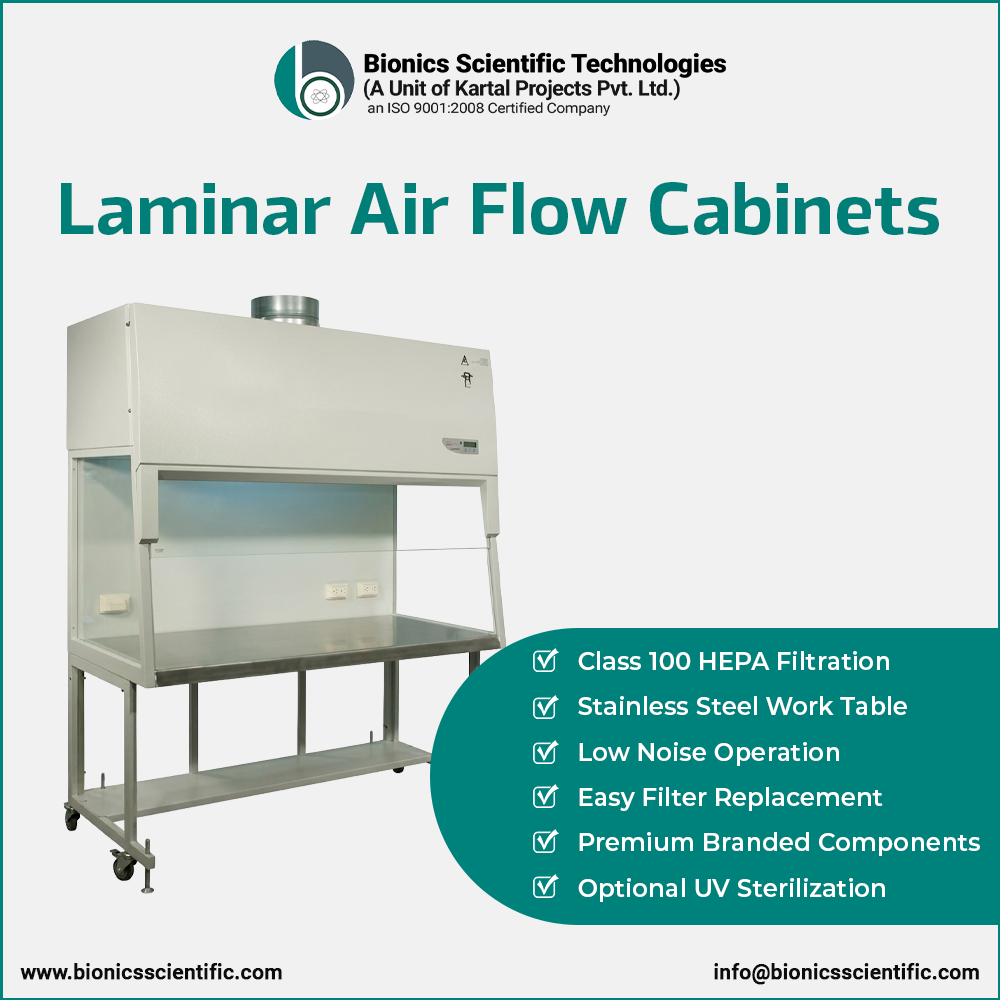

Laminar Air Flow Cabinets - Laminar Air Flow Bench

Laminar Air Flow Horizontal & Vertical cabinets

Laminar Air Flow: Many microbiological and cell culture laboratories require a highly sterile working environment for performing research activities, and laminar air flow cabinets are the best solution for them. A laminar air flow (LAF) cabinet, also known as a laminar hood or tissue culture hood, is an enclosed cabinet designed to prevent contamination of biological samples, semiconductor wafers and sensitive materials. In other words, the laminar air flow cabinet provides an excellent clean air environment, which is free from contaminants for performing a number of laboratory requirements. These laminar cabinets are used for general laboratory work and in the electronic and pharmaceutical industries extensively, and the laminar air flow is also called clean benches somewhere, as the working air environment remains clear due to the high-end filtration process. Industries demand both horizontal and vertical laminar air flow cabinets for different purposes. A laminar air flow cabinet maintains a unidirectional flow of HEPA-filtered air over the work area and protects the working environment from dust and other airborne particulates. The flow can be horizontal (parallel to the work surface) or vertical (from the top to the work surface). Both air flow types have their significance in the research. The question is where to use the horizontal air flow cabinet or vertical air flow cabinet. This choice solely depends upon the requirements of the applications.

Working Principle & Parts of Laminar Air Flow

Laminar air flow or laminar hood consists of a stainless steel cabinet, filter pad or pre-filter, HEPA Filter, fan or blower, UV lamp, working stations, fluorescent lamp, etc. These important parts perform individual functions during their operation. The main function of laminar air flow is to remove all airborne contaminations to maintain sterile conditions. This process takes place in the following way:

- Step 1. The laminar cabinet uses an inward flow of air passed through one or more HEPA filters to create a sterile environment.

- Step 2. The air taken inside via a filtration system is exhausted across the work surface.

- Step 3. Primarily, air is passed through the filter pad that ensures the streamlined flow of air into the cabinet.

- Step 4. After that, the blower directs the air towards HEPA filters.

- Step 5. The HEPA filters capture fungi, bacteria or other particulate materials and make air circulating inside the cabinet particulate-free.

- Step 6. Some effluent air passes at the bottom rear end of the cabinet via perforation, while most of the air passes over the working bench (it is the area encompassing burner, loops and culture plates inside the laminar cabinet where all processes take place) towards the face of the operator.

Vertical Vs Horizontal Laminar Flow

As mentioned above, in a horizontal laminar air flow cabinet, filtered air blows across the work zone in a horizontal direction; this constant flow of air provides material and product protection. Whereas, in a vertical laminar air flow cabinet, filtered air blows into the work zone and leaves through the holes in the base. As compared to the horizontal type, vertical flow cabinets can provide greater operator protection. Furthermore, it is user preference that decides which type of laminar air flow cabinet you should use.

#1 Laminar Air Flow Cabinets Manufacturers in India

We are ISO & CE Certified laminar air flow Manufacturers in India, Laminar Cabinets suppliers in Delhi NCR, India & Overseas. We have more than 35 years of manufacturing of laminar hoods or tissue culture hoods in India. These laminar air flow (LAF) cabinets are available in 5 standard sizes that can be further customized to meet the unique requirements of our customers. These cabinets are well-suited for cell culture and microbiological applications that require class 100 air quality.

Our laminar air flow cabinets are modern in design and feature certified quality construction; with options and accessories, these prove to be the most efficient laminar air flow cabinets available on the Indian market today. Our in-house manufacturing and fabrication facilities provide benefits for any kind of customization that our customers may need. In addition to covering all Indian markets, these laminar air flow cabinets are also exported worldwide. To find out the price list and other important details, please email us your query and our sales team will coordinate with you till you get 100% satisfaction.

Precautions to follow while operating laminar air flow

- Before and after the operation, the cabinet needs to be sterilized with UV light.

- It is mandatory to switch off the UV light while performing any work.

- The airflow and the UV light need not be used at the same time.

- The operator must wear long gloves and lab coats while operating the laminar air flow cabinet.

- After completion of the work, the cabinet, glass shield and other components need to be sterilized carefully.

Laminar Air Flow Features:

| HEPA filtration unit provides Class 100 air quality | Meet US Federal Standard 209 B (BS 5295) |

| Optional UV lamp to sterilize work zone | Stainless steel work table |

| Low noise level | Made from branded parts (blower etc.) |

| High airflow capacity | Easy to change filters |

Standard Dimensions

| Model | BST/VLAF-22 | BST/VLAF-32 | BST/VLAF-42 | BST/VLAF-62 | BST/VLAF-82 |

|---|---|---|---|---|---|

| Working Size | 2’x2’x2’ | 3’x2’x2’ | 4’x2’x2’ | 6’x2’x2’ | 8’x2’x2’ |

| Size of HEPA Filter | 2’x2’x6” | 3’x2’x6” | 4’x2’x6” | 3’x2’x6” | 4’x2’x6” |

| No. of HEPA Filter | 1 | 1 | 1 | 2 | 2 |

Laminar Air Flow Cabinet Specifications:

| Cleanliness | Class 100 |

| Velocity | 90 FPM ±20% |

| Hepa Filter | 99.999 % efficiency for particles >0.3 μm |

| Pre-Filter | 85 %efficiency for particles >0.5 μm (Washable) |

| Particle Count | Better than US Fed Std 209B Class10 and VDI 2083 Class 3 |

| Cabinet | Laminated High Quality Wooden Board /PCRC Sheet Powder Coated/Stainless Steel SS 304 (optional 316 grade) |

| Work Table | 304 Stainless Steel (optional 316 grade) |

| Airflow Speed | Control Speed Controller (Three Step Speed Controller) |

| Blower | High efficient centrifugal type with lifetime lubricated bearings |

| Light | High intensity, low wattage >800 lux |

| Noise Level | <55 dBA |

| Standard Accessories | Air/gas cock and mains power socket (16A) |

| Power Supply | 220-230 V,50 Hz. |

| Optional Accessories | - Microprocessor LCD Controller - Digital display for air flow rate - Transparent Front Door - Gauges Pressure (Statics Pressure Mano-Mater) - Magnahelic Gauge (for filter pressure) - U. V. Germicidal Tube in work area - Electronic Filter choke alarm - Spare HEPA Filters - Auto switch on/off for U.V. Germicidal tube & fluorescent light - Hour Meter for UV light |